Advantages of Computer Integrated Manufacturing

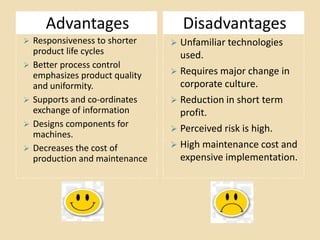

Computer integrated manufacturing has the advantage of possessing intelligence to maximise the process provided process is well understood and all parameters can be measured in real time. Ad Siemens is Transforming Business Models and Helping Build the Next-Generation Workforce.

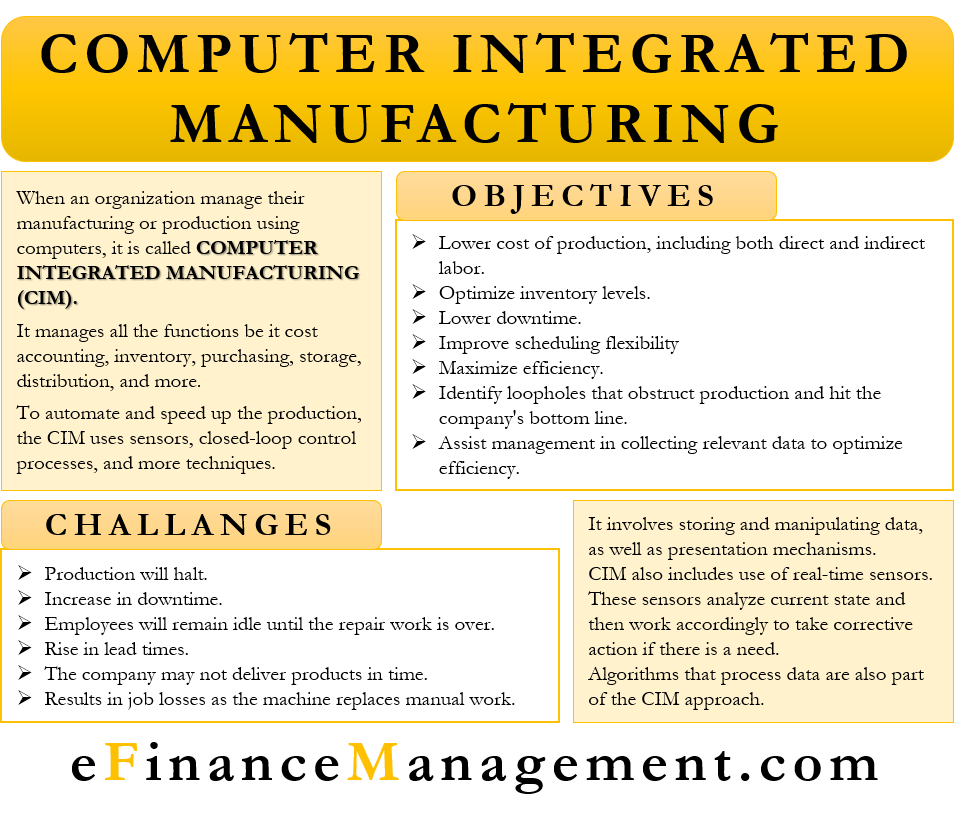

Computer Integrated Manufacturing Cim Meaning Objectives And More

Typically CIM relies on closed-loop control processes based on real-time input from sensors.

. Computer Integrated Manufacturing System 1. Hardware solutions to meet the needs of IT OT professionals in manufacturing facilities. Manufacturing strategy the paper noted that the suitability of CIM to the entire aim and objectives of a manufacturing company must be duly considered before the adoption of the production strategy to ensure that it offers the firm the much needed competitive advantage.

Technical Support About Support Contact Support Field Service Installing TeamViewer Roll Forming - Whitepapers and Presentations A Case for Computer Integrated Manufacturing CIM Basic Methods of Length Control Benefits of Computer Integrated Manufacturing CIM - Deutsch Coil Handling Continuous Improvement - Tube Pipe Journal Continuous Improvement in Roll. Better use of materials and machinery. Plants that integrate CIMS are.

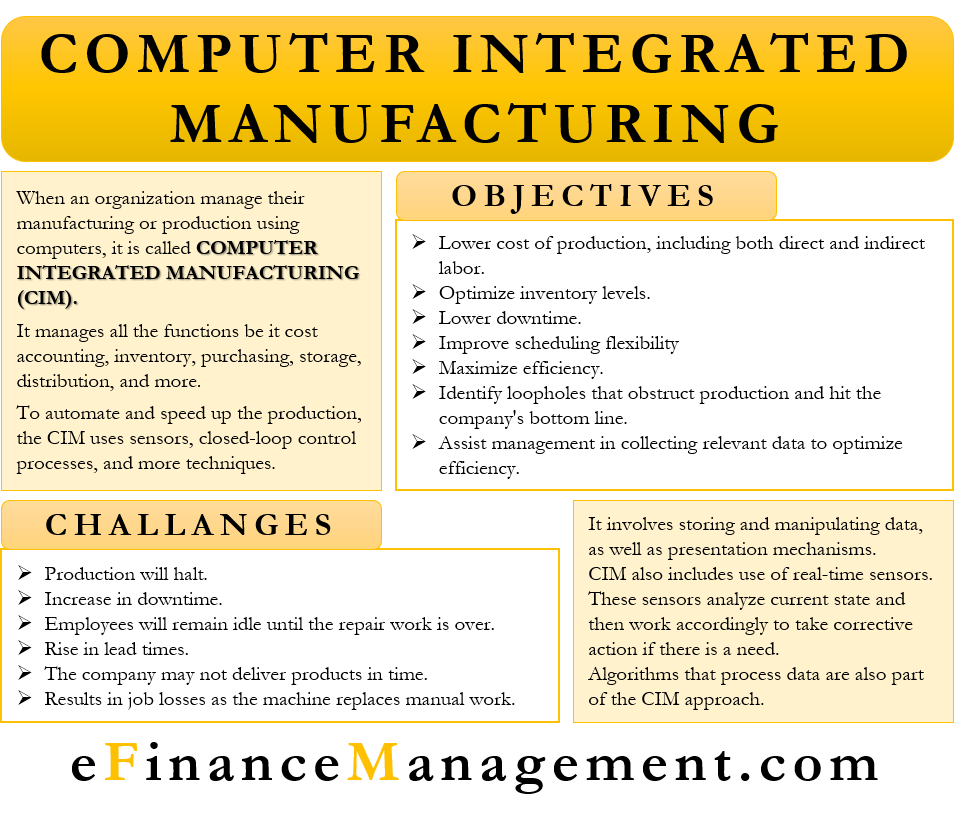

Computer integrated manufacturing CIM have many advantages over traditional manufacturing methods as we can say It improves the quality. Profit margins go up and expenses go down. A system of manufacturing that uses computers to integrate the processing of production business and manufacturing in order to create more efficient production lines.

The lower the lead time the less wages that need paid and the more products will be supplied to the consumer. Leading the Way by Creating a Fully Automated Customer-Oriented Manufacturing Process. Improved accuracy and time savings can translate into reduced costs and process time for operation.

NRC once again states that using computer integration such as from solidworks cam will have positive impacts. Ad Digital Integration for Manufacturing with End-to-End Optimization and Accountability. Information handling is the way to reduce manufacturing time.

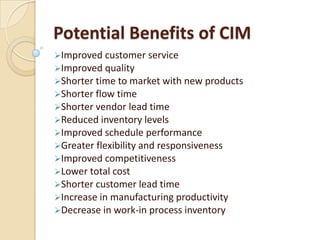

The main advantage of CIM is the ability to create automated manufacturing processes. Computer-integrated manufacturing systems are useful for making manufacturing decisions and ensuring that a manufacturing plant maintains correct inventory levels. Programmable computer based manufacturing system.

Computer Integrated Manufacturing CIM CIM integrates production administrative and support functions in a manufacturing firm by tying together separate automated systems and minimizing administrative and manual functions ERP and CRM Electronic Flow of Information Related to All Aspects of the Manufacturing Process. Manufacturing computer integrated manufacturing. Better use of capital resources through work automation results in higher productivity and.

Ad Built to perform in challenging and harsh environments for critical IIoT applications. Adoption of a computer integrated manufacturing CIM system allows to achieve a higher accuracy level. Computer-integrated manufacturing CIM is a system consisting of software covering many business processes including integration of automated assignment and reporting of factory floor operations through machine and material handling equipment sensors and software.

Create More Agility to Become a Market Leader in Digital Manufacturing with EYs Expertise. Increase flexibility in manufacturing. CIM covers enterprise resource planning ERP.

Computer Integrated Manufacturing CIM CIM integrates production administrative and support functions in a manufacturing firm by tying together separate automated systems and minimizing administrative and manual functions ERP and CRM Electronic Flow of Information Related to All Aspects of the Manufacturing Process. CIM is the architecture for integrating the engineering marketing and manufacturing functions through information technologies. In the broad sense CIM involves the integration of all the business processes from.

A fully automated system can operate much faster and work 247 if required. The lead time can be reduced from twenty to sixty percent. Benefits of computer integrated manufacturing.

Some of the benefits of computer integrated manufacturing systems are. It is also known as flexible design and manufacturing. Implementing technology into your manufacturing process allows you to achieve near-perfect.

This allows for greater flexibility and control over the production process as well ensuring a manufacturers ability to provide enhanced quality control. It has been established that in metal cutting virtually every parameter related to process can be determined if the shear angle is known. Typically it relies on closed-loop control processes based on real-time input from sensors.

Reduces the delivery time. Advantages And Disadvantages Of Automation Control In Industry 3. The benefits of computer integrated manufacturing include not only optimizing the production and business processes but also providing data storage data processing and real time sensors.

Computer Integrated Manufacturing

Computer Integrated Manufacturing

Chapter 15 Computer Integrated Manufacturing Systems Ppt Video Online Download

Computer Integrated Manufacturing What Why How N Ix

0 Response to "Advantages of Computer Integrated Manufacturing"

Post a Comment